When purchasing a threaded pipe, hose or a bolt/screw of any sort, the many thread types can be overwhelming. Here’s a breakdown of the most common threads that are used today on different items around the house.

Just a heads up, this page contains affiliate links. If you buy through them I earn a small commission. If you chose to buy through these links I truly thank you for your support! – Jake

In general, there are eight common thread types you may see around the house or garage:

-

- Unified National/SAE (UNC/UNF/UNS)

- Metric parallel

- Metric tapered

- National Pipe Thread Tapered (NPT/NPTF)

- British Standard Pipe Parallel (BSPP)

- British Standard Pipe Taper (BSPT)

- Garden Hose Thread (GHT or NHR)

- Type 1 (Used on propane tanks)

Aside from the obvious GHT and Type 1 threads, here are some things you may find these threads on:

-

- Machine screws, bolts, and fittings

- Unified National/SAE threads (UNC/UNF)

- Metric parallel

- Threaded pipe, hot water supply, faucet connector, flexible gas hose

- National Pipe Thread Tapered (NPT/NPTF)

- British Standard Pipe Parallel (BSPP)

- British Standard Pipe Taper (BSPT)

- Hydraulic Components

- UNF, BSPP, BSPT, NPTF, Metric parallel, Metric tapered

- Toilet Water Supply

Note – Wood screws, metal screws, masonry screws, and similar “pointed” screw thread types won’t be covered here.

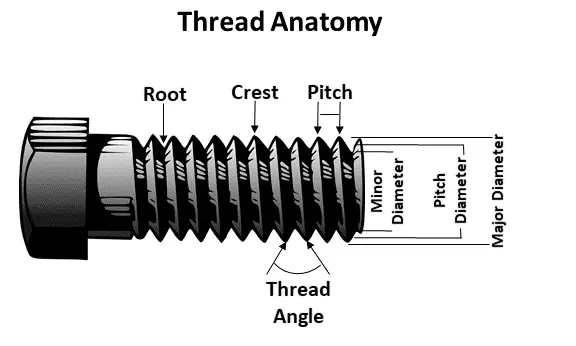

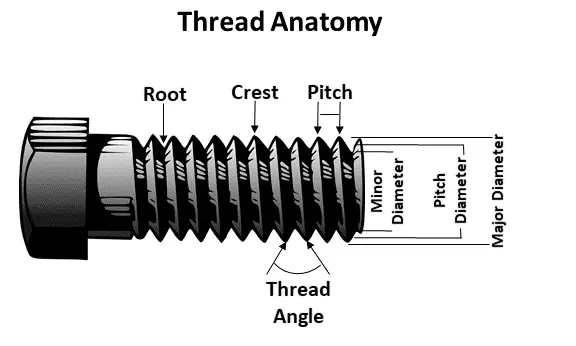

Thread Anatomy

To understand different thread types it is best to first learn the anatomy of a thread:

The root is the bottom of the “v” between each thread. The crest is the peak of a thread. The pitch, in metric threads, is usually measured as the millimeters between each crest. With standard threading, the pitch is measured in threads per inch (TPI). The major diameter is the diameter at the widest point of the threads.

It’s not shown in the above diagram, but tapered threads have a slightly narrower diameter near the tip and slightly wider diameter towards the head. The amount by which the threads taper is known as the taper angle.

Machine Screws and Bolts Thread Types

These items will typically use Unified National (UN), or metric parallel threads.

The two most common types of Unified Threads are the UN Coarse (UNC) and UN Fine (UNF). ANSI B1.1 is the standard that defines how many threads per inch for any given diameter of UNC or UNF fastener.

The standard for metric parallel threads is given by International Organization for Standardization (ISO) 68-1, 261, 262, and 724. Metric fasteners also commonly come with coarse (1mm pitch) or fine (1.25mm pitch) threads.

Identifying Machine Screws and Bolts

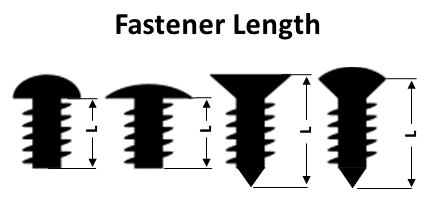

Machine screws and bolts are identified by the major diameter, pitch, and length.

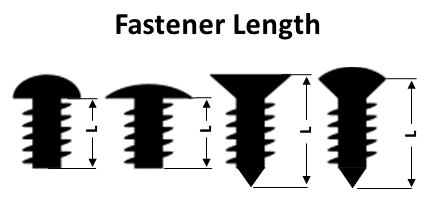

In general, the length of any fastener is measured from the tip of the fastener to where the head of the fastener meets the mating surface (i.e. wood, metal, etc.). Here are a couple examples:

Standard and metric machine screws and bolts are notated slightly differently.

For example, a 3/8″ diameter hex bolt with 16 threads per inch and 1″ long is notated as 3/8 in.-16 x 1 in. A 12mm diameter metric bolt with 1.25mm pitch (fine threaded) and 35mm long is notated as an M12-1.25 x 35mm.

Take special note that metric threaded items may only list the pitch when it doesn’t have coarse threads (1mm pitch). For example, you may see a M14-1 x 35mm bolt listed as M14 x 35mm.

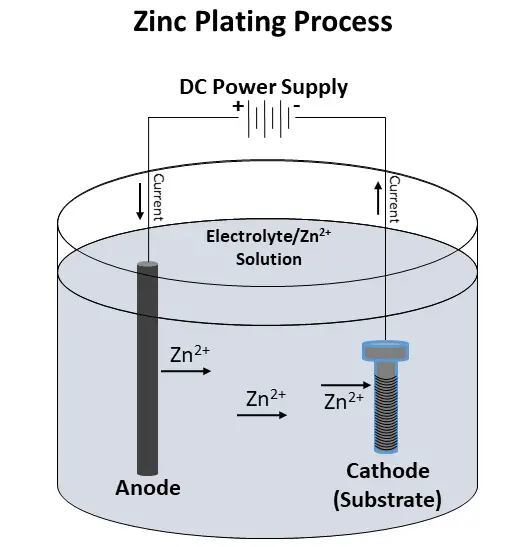

Machine screws and bolts are commonly zinc-plated or galvanized to resist corrosion. This is what gives them a shiny or dull gray appearance.

UN and Metric Thread Identification

You can identify UN and metric threads by using two simple tools, the pitch gauge and the calipers.

A pitch gauge like this one is cheap and extremely handy when trying to find a suitable replacement for a broken bolt or screw.

A digital calipers like the one shown below

A digital calipers like the one shown below is a necessary tool for identifying the exact diameter and length of a screw or bolt.

Coarse vs Fine Threads

If you ever wonder when you should use fine threads and when you should use coarse threads, you aren’t alone. There are advantages of using each:

Coarse

-

- Faster assembly

- Minor thread damage is less likely to affect assembly

- Less chance of stripping in weak materials (i.e. wood)

Fine

-

- Higher tensile strength due to more surface area

- Higher shear strength due to larger minor diameter

- More precise adjustment

- Easier to tap than coarse threads

- Less tendency to loosen

Depending on the application and fastener requirements, coarse or fine threads may be a good choice based on the advantages given above.

Threaded Pipe, Hot Water Supply, Faucet Connector, and Flexible Gas Hose Thread Types

Threaded Pipe Thread Types

If you live in the US or Canada, threaded pipes most likely have National Pipe Thread Tapered threads (NPT) or National Pipe Thread Tapered Fine threads (NPTF). These threads are described by the ANSI B1.20.1 and ANSI B1.20.3 standards.

NPT threads create their seal through a very tight seal between male and female threads, thanks to their taper. Always use a sealant tape or compound with these threads to ensure a good seal.

NPTF threads, on the other hand, don’t require the use of a sealant tape or compound. This type of thread has a root and crest shape that allows the threads to actually deform to create a mechanical seal. Another name for NPTF threads is Dryseal American National Standard Taper Pipe Thread.

If you don’t live in North America, chances are your threaded pipe uses British Standard Pipe Parallel (BSPP) threads or British Standard Pipe Taper (BSPT) threads. These thread types are based off the standards set in ISO 7 (taper) and ISO 228 (parallel).

Hot Water Supply, Faucet Connector, and Flexible Gas Hose Thread Types

Hot water supply lines, faucet connector hoses, and flexible gas hoses commonly use NPT threads. You may see threads on these items labeled as MIP/FIP (Male Iron Pipe or Female Iron Pipe). Just know that NPT and MIP/FIP are interchangeable.

Hydraulic Component Thread Types

Hydraulic component threads use many types of threads, depending on the fitting and application. UNF, NPTF, BSPP, BSPT, metric parallel, and metric tapered are all potential thread types used on hydraulic components.

Metric tapered threads are similar to metric parallel threads except the tapered threads are, obviously, tapered.

Identifying Hydraulic Component Threads

Parker Hannifin has a great guide on identifying hydraulic component threads.

Garden Hose Thread

Garden hoses and related fittings have their own type of thread called, unsurprisingly, Garden Hose Thread (GHT).

This thread type is officially known as National Hose (NH) thread and is based off the standards given in ANSI B1.20.7.

Male and female GHT threads may also be identified as MHT (Male Hose Thread) and FHT (Female Hose Thread), respectively.

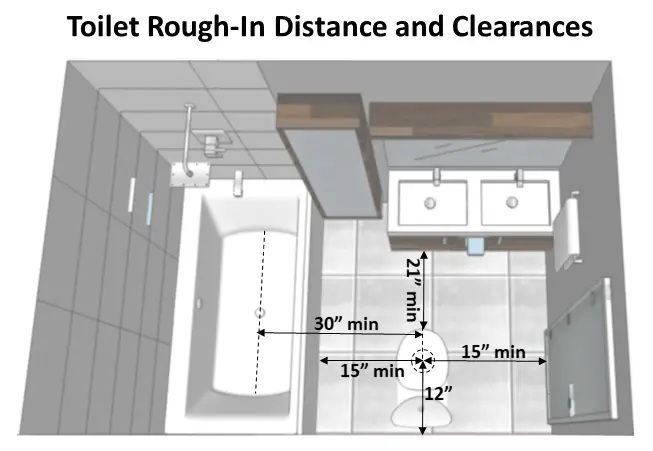

Toilet Water Supply Thread

Toilet water supply lines and related fittings have a type of thread known as 7/8″ Ballcock. This is a parallel thread type that is equivalent to 15/16″-14UNS thread.

Propane Tank Thread Types

A typical BBQ propane tank and hose commonly utilize a thread type called Type 1. However, there are other thread types propane components use as well. Etrailer has a great article on identifying thread and fitting types on propane tanks and accessories.

There’s no doubt that there are a ridiculous amount of thread types out there. This can lead to a lot of confusion on what is compatible with what. Just remember to always use the same thread type when replacing screws/bolts, fittings, hoses, etc. While it might seem like two different standards of pipe threads fit together, it’s just not worth the risk of a leak in the long run.